Following the success of the initial and second cargo quad conversions (and to be honest, missing the versatility of the cargo carrier in our fleet), thoughts turned to making another one, though this time making the complete frame instead of doing a conversion of another trike.

Significant time was spent staring at a drawing program until I thought I had enough details to start fabrication. This one would be made from common mild steel as for some reason it is quite hard to find more exotic materials in small quantities in this country. And for a prototype that was likely to see several modifications readily available materials were the go!

The specification was again based around using a Bafang e-assist kit, an internal geared hub as a transmission, and as near as a 600 x 600mm cargo platform as practical. To save some time we re-cycled (get it?) some parts salvaged from written off trikes, being the steering knuckles and the seat.

Construction progressed – somewhat leisurely to be sure – but it did progress. Many times I looked at the parts and thought that can’t be right, it’s too short/long/etc and I had to remind myself that as it fits “on paper” (on pixels? en-pixelated?) it should fit in real life. And in the end the only thing I had to change was the adjustable boom length, and that was because I picked up a piece of tube that looked the right length, or at least not too short!

Assembled at last, and it did actually fit much to my surprise and everybody else’s amazement. The most annoying error was in the recycled parts – my measuring of the steering knuckle parts was not accurate enough and the wheels are not quite vertical. But at least both are not quite vertical in the same way.

As mentioned, the transmission is designed around using a DIY mid drive e-assist kit, in this case a Bafang BBS01 250W version, but options like the CYC Photon or Tong Sheng mid drives would also fit.

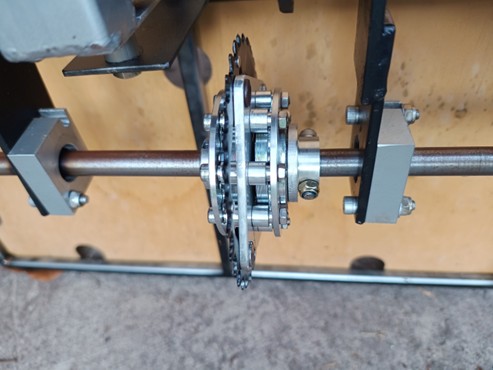

Conventional (for a recumbent that is) chain drive runs back to a mid mounted internal gear hub, a Sturmey Archer RK8W in this instance to handle the gear changing, and on to a less conventional final drive using 30T/32T chainrings to take the power to the rear axle. Almost any disc brake compatible internal geared hub would be usable, but I’m inclined to think an Enviolo CVT hub with the AutomatiQ gear change system would be the bees knees.

Mounted centrally on the rear axle is the double freewheel doing service as a pseudo differential. This does the job of allowing the rear wheels to rotate at different speeds as needed when turning corners, it doesn’t however split the drive between each wheel but instead sends the drive to the slowest turning wheel.

In practice you get continuous drive with almost no wheel spin under power – you can almost feel the wheel spin before drive is directed to the other wheel. This double freewheel (using BMX parts) is not seen as a long term solution as manufacture and assembly is time consuming and fiddly, although service parts are readily available and cheap.

The overall weight is not insignificant at a few grams under 40kg, but for an e-assist equipped cargo hauler it is competitive with commercial bike offerings, eg an Urban Arrow starts at 48kg and climbs from there. As you can imagine, bike weight is not really a consideration when hauling cargo is the aim!

Specifications (for this version):

| Seat Height | 330 mm |

| Bottom Bracket height | 395 mm |

| Wheel Base | 1210 mm |

| Width (max front wheels) | 860 mm |

| Wheels | 406 mm |

| Brakes | 160mm disc brake |

| Load Area | 600 x 580 mm |

| E-Assist | Bafang BBS01 |

| Mid gearbox | Sturmey Archer 8 speed IGH |

| Gear Range | 23.5 – 77 G.I. |

| Seat Angle (min) | 42 degrees |

| Steering | Indirect, crossover. |

| Weight w/battery | 39.5kg |

| Frame material | Steel |

Test riding didn’t reveal any nasty surprises although the original Bafang 46T chainring made the gearing much too tall. An adapter was made and a 34T chainring fitted, improving the overall gearing immensely. At least now if the e-kit dies there is some hope of getting home again!

The steering was quite highly geared, meaning that small handlebar movement gives a proportionally larger wheel response. This isn’t really noticeable in normal riding other than to make the steering feel heavier than a sports trike. But that’s in keeping with its mission, I guess, but is something we will experiment with at a later stage. The two wheel drive using double freewheels also conspires to keep the quad tracking straight.

Having two chain drives gave some pause for thought. While it is not at all unusual in the recumbent world, we have tried to make it as simple and maintenance friendly as possible.

The primary drive (from the pedals to the mid gearbox) has only one power idler and the chain tensioner. This actual quad has an optional chain gobbler as well. One chain tube is fitted to guide the chain under the crosstube and steering gear, permanently mounted it keeps the chain aligned and clear of all moving bits. The final drive only needed a chain tensioner to manage the chain.

The chainrings selected were decided based on fitting the largest practicable size to lower the chain tension (and hence wear), but in reality, were really determined by the sprocket available for the Sturmey Archer hub, ie 25T. In the end we chose a 34/25 primary drive, and 30/32 final drive. This works admirably with the e-assist yet is still low enough to ride un-assisted.

Is this the final design?

No, of course not.

This one is very usable as is and will be used as an alternate to a car where possible and improvements will be noted as they appear. We don’t envisage much change to the basic geometry and mechanicals but of course the door is wide open to customisation!

Final Note

We now have our DT Recumbent Cargo Quad Web page up and running.

Pricing starts from AU$7,200 for a single-wheel-drive version with a Bafang e-assist and Sturmey Archer IGH. Two wheel drive version from AU$7,700. Check out our Cargo Quad web page for all the specs and options.